Fine blanking - Digitalization of the Lubrication Technology as an entry into “Industry 4.0”

The name Feintool is inseparably connected with the fineblanking technology. The Feintool AG has refined the technique of Fineblanking in the metal forming industry for decades and is considered the innovator and trendsetter in the fineblanking field.

Many suppliers of the automotive industry, the electrical engineering industry, as well as the medical device industry rely on Feintool AG equipment and tooling for their high-precision parts. The Feintool AG is known and operates under the name “Feintool System Parts AG”, and is a vital producer and supplier of precision stamped and formed parts, with multiple locations worldwide. The quality of these parts is ensured, among other things, by Raziol Lubrication Technology. The sophisticated lubrication technology provided by Raziol guarantees precision parts and maximizes tooling up-time.

By Dietmar Kuhn

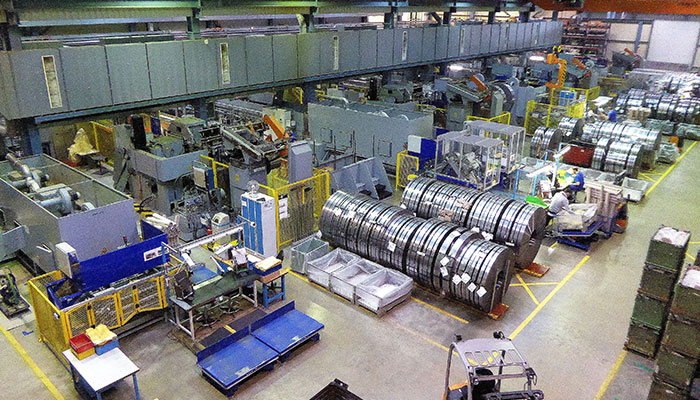

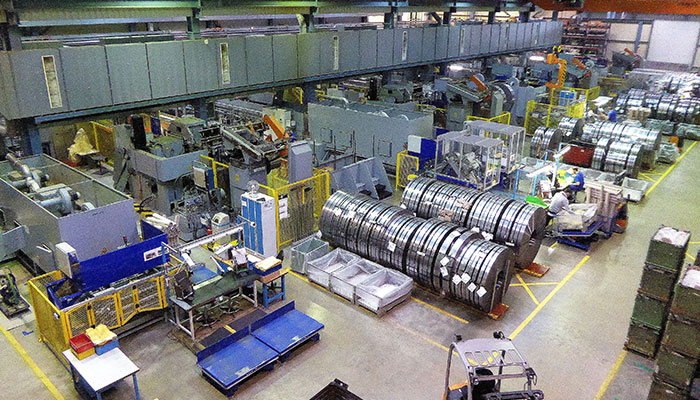

Upon entering one of the production facilities at the “Feintool System Parts GmbH” in Jena, you will immediately notice numerous stacks of steel coils. In the background you can hear the press-stroke sounds of the fineblanking presses, producing precision parts in a fast pace environment. Several Feintool-HFAplus fineblanking presses are lined up in a row, producing stamped and formed parts of the highest quality—namely fine-blanked parts. They will be utilized as high-tech-components especially in the automotive industry, however, they are also in high demand in other fields such as the electrical/electronic industry, the machine-building industry, and the medical technology.

Feintool System Parts in Jena is one of several Feintool operations worldwide producing high-precision metal parts. Feintool System Parts AG is considered a leading supplier for nearly all premium automotive companies. There is rarely a well-known car on the road today, that does not feature a Feintool component installed in its transmission, seat adjustment mechanism, or is part of the other building blocks needed in a vehicle.

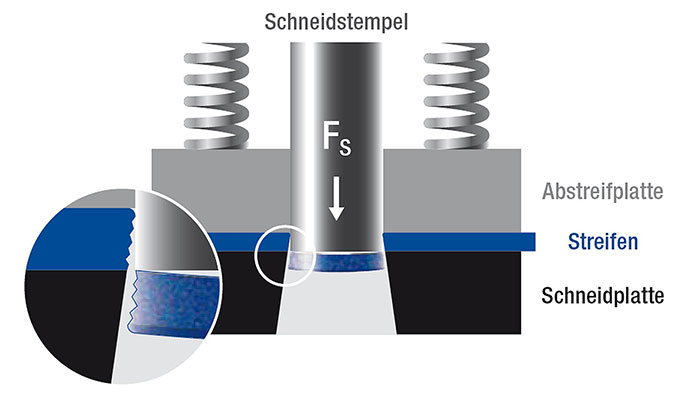

Feintool is regarded as the inventor of the Fineblanking technology and is furthermore considered the technology leader providing a wealth of experience coupled with an emphasis on outstanding quality. Although the Fineblanking process shares many similarities with conventional stamping the fineblanking process features a much higher accuracy standard. For example, conventional stamping produces parts that have a clean-cut and fracture zone, whereas the fineblanking process employs a “V-ring and a counter pressure force. The two forces control the flow of the material. The main punch will then force the material into the die cavity. The counter-punch force maintains the flatness of the part. This unique process gives all fineblanked components a right-angle edge with a fully smooth surface.

Therefore, the fineblanking process provides opportunities to combine the cutting and forming process using a progressive tool design, facilitating the production of complex components with a single stroke of the press. Parts are ready for installation without the need for additional processing. In a high-volume production setting the fineblanking process ensures the ability of high-quality, multi-functional parts to be produced in an economical fashion.

Feintool System Parts Jena, covers the entire process chain relating to the fineblanking technology. This starts with customer advice and support on part design, recommendation on optimal and specific material choice, up to an economical and innovative tool design and the actual production technique on Feintool presses. Naturally, it includes the lubricant and lubrication technology. In Jena, the management and highly motivated employees as a team master the fineblanking technology form A-Z.

For the fineblanking experts at the Jena operation the lubrication and lubricant technology is of utmost importance to guarantee the manufacture of components of highest standard, quality and precision. Especially, innovative manufacturing processes such as fineblanking demand an optimum lubrication technology and lubricants that guarantee a high tooling up-time and ensure an almost 100% of defect-free products in a safe, controlled and consistent production process. Hence, the meticulous coordination of lubricants, the application technology of the lubricants, the workpiece materials and the tool design is the guarantee for a reliable and value driven production process.

“Feintool System Parts” demands that the above-mentioned standards are met when selecting their suppliers. Only reputable companies of highest quality standards are considered. Feintool Jena decided on the decades of experience offered by the Tribology Specialists Raziol Zibulla & Sohn, Iserlohn, to be the supplier of choice for all lubrication related technologies.

Raziol has been known in the stamping/forming and deep drawing industry for over 70 years, and is considered by many as the go-to supplier for efficient, accurate and safe lubrication technology. This family business develops and produces a variety of high-performance and custom-blended lubricants. In addition, Raziol is the leading supplier of lubricant application technology. Raziol’s highly engineered systems precisely meter and accurately apply the needed lubricants (sectorial or partial) on sheets and coil strips. The Raziol portfolio offers a suitable solution for every customer and every requirement.

This is also evident at the Feintool Jena company where Raziol Lubrication Systems are installed on numerous Feintool fineblanking presses. The main focus there is on the Raziol spray system SKT-HFAplus 450/18-50-H3. The number 450 indicates the maximum lubrication width of the coil strip where by selection one of three lubricants can be applied, either sectorial, partial, or in full width setting. Depending on the product or strip, the operator can switch with the push of a button from one of the three lubricants to the next.

In addition, the SKT Raziol System features a spraying control program, a heater, as well as an integrated lubricant supply unit. The latter consists of three 40 Liter pressure tanks for the three different types of oil which are installed right next to the fineblanking press. Currently, the pressure vessels are filled by hand. Development is in the works for a future system to automatically re-fill the tanks. The re-supply barrels would be located in the basement and connected to the 40 Liter pressure tanks. Float switches control the oil level of the tanks and initiate the refilling process as needed without interrupting the stamping process.

To guarantee a reliable supply of the lubricant a flowmeter is installed at the pressure tanks. The Raziol control unit registers 820 pulses/liter. The Raziol flowmeter provides the customer with an online monitoring system enabling consumption control of lubricants to be applied to blanks and strips.

The Raziol Flow Measurement Systems can either be used as a self-sustaining system or can be incorporated into a roller lubricator and spray-system concept. Prior to leaving the Raziol plant each system is calibrated according to the customer specifications in regard to the desired metering range and the chemical/physical properties of the lubricant. Raziol offers an annual maintenance contract and if necessary a recalibration of the device. The Raziol quality monitoring system guarantees the user a safe, effective and accurate lubrication, resulting in higher economic efficiency.

At “Feintool System Parts” in Jena, a premium version of the Raziol spray system is installed and in operation. This premium system offers a product-specific data storage of the desired lubrication quantity, registers and records the established spray pattern, and identifies the lubricant being applied. The Raziol control checks the flow volume, monitors the tank level and records these parameters for future consultation if needed.

For Mario Krause and Kai Wiegand at Feintool Jena, the Raziol Spray System concept is especially important. Mr. Krause and Mr. Wiegand are equally responsible for the process optimization, the outstanding product quality, high product output level as well as addressing environmental concerns and improving economic effectiveness. A state of the art lubrication spray system from the Raziol Company plays a central role in accomplishing these tasks.

In the near future, and in cooperation with the Tribology experts of the Raziol GmbH, Mr. Krause and Mr. Wiegand plan to integrate their system into the Industry 4.0 program. That means a precise consumption monitoring of the lubrication and the metering of the applied oil quantities which is being supported by a Raziol developed automatic calibration program. The entire system and/or the entire production network can then be programmed, controlled, regulated and monitored online.

The program includes a fully automatic adjustment of the lubricant quantity (g/m2) and a daily log of operational data recording. It also carries out "automatic calibration checks" for the spray nozzles, including evaluations using the integrated controls.

The Raziol control system and data management program will provide relevant up-to- date process information instantly. By using this system, Feintool System Parts expects to be able to facilitate an intelligent and flexible production environment.

To evaluate the individual production runs, the process history of each run is collected, processed and stored in the appropriate data file location.

Mr. Krause and Mr. Wiegand will have the ability to recall individual runs and create a comparison table for review to detect any abnormalities, make changes to the lubrication program if needed, and fine-tune the process at any time during the production run.

Pictures:

Feintool System Parts is considered a fineblanking leader worldwide. Annually the plant in Jena produces tens of millions of high-precision parts for the automotive and electrical industries, the medical technology and mechanical equipment industry.

The “Fine” difference: Image 2a; Conventional stamped parts show edge surfaces with a smooth cut, (max 1/3 mat’l thickness) as well as with a break-away portion which impacts part flatness. In the image 2b the embedment ring, force FR and the counter holding force FG clamp the material. Then the cutting force FS will be activated. This allows a clean, perpendicular edge and an absolutely flat part to be produced.

View of one of the manufacturing halls with the Fineblanking Press --Feintool Schuler 8800 HFA (HFA = hydraulic fineblanking equipment), showing the integrated coil handling and straightening equipment.

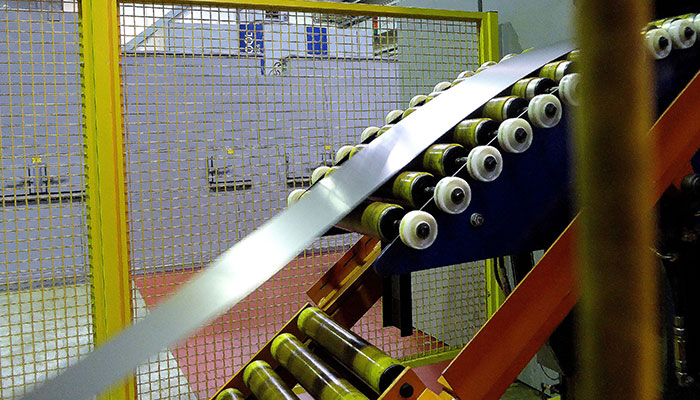

The coils up to 400 mm wide are placed on a moving cart and thus placed onto the de-coiler.

Utilizing a material-loop bridge. The strip is inserted into the straightening equipment which acts also as the material feed unit.

The fineblanking press produces parts using different materials, thus the requirement for different lubricants. Therefore, the Raziol lubrication equipment is designed for three different lubricants. Switching from one lubricant to the next is done automatically by the push of a button.

The Raziol Company lubrication experts have delivered a complete system to Feintool Jena, which includes the metering control, and heating of the lubricant. The three pressure tanks shown in the image # 7 (yellow container), are part of the complete lubrication system.

The example above shows the control panel at the press displaying the lubricant selection page.

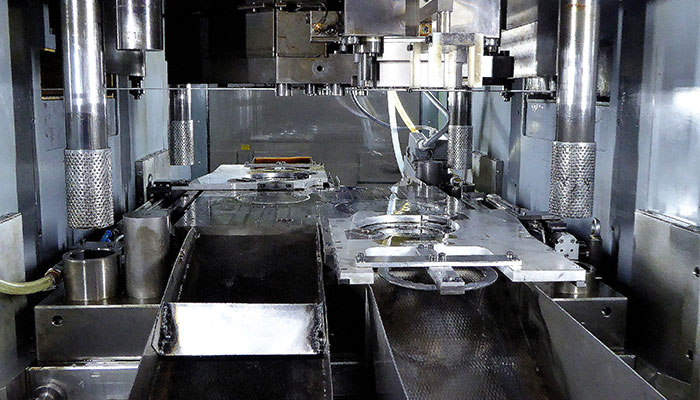

A view into the tool location area of the HFA 8800.

A view of the spray chamber which is extended out of the housing for service. It contains all necessary connections and supply lines for the air, lubricant and electric requirements. The main nozzle bar is designed in compact form and uses 9 nozzles with a 50mm pitch dimension for the maximum lubrication width of 450 mm. All the nozzles are fixed to the main bar. The lubricant and air is supplied thru the main bar. No additional tubing is needed.

Mr. Kai Wiegand, lean management leader at Feintool, is an expert in the fine- blanking technology. His expertise, coupled with the importance of the lubrication technology, is key to ensure part quality and important to improve the tooling uptime. He is in constant communication with the Raziol Company to implement “Industry 4.0” in combination with the lubrication technology.

Various parts manufactured by Feintool with the fineblanking technology. Just a small sample of the thousands of products produced using the fineblanking technology. The focus being the automotive industry.

Images by: Feintool

High resolution flow meter by Raziol. The high-precision components, in combination with intelligent evaluation programs, can document the lubricant quantities as small as 25 µl with the flow direction. Thus, guaranteeing a constant and reliable application of the lubricant.